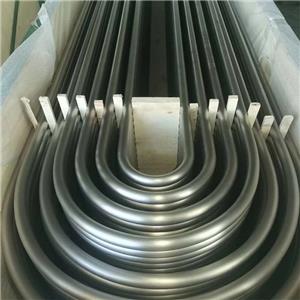

Quatro métodos de processamento de tubo soldado de titânio

Titanium welded pipe generally has the following four processing methods:

1. Tabletting welded titanium pipe: compared with the multi seam

2. Multi weld seam type (shrimp waist type) Titanium pipe: its processing technology is complex. It is usually made by cutting the pipe into multiple oblique openings, welding, or forming multiple sections under the plate, and then rolling and welding. This method has a large amount of residual materials at the edges and corners and a large amount of welds. Because the weld seam will greatly reduce the corrosion resistance, easy to leak, and the appearance is poor. The inner surface is a folded surface, which increases the transmission resistance of the pipeline, increases the scouring corrosion on the back, and reduces the service life.

3. Stamping titanium welded pipe: the appearance of this titanium pipe seems to be no different from that of the pushed titanium pipe, but the processing process is to punch the pipe billet in the stamping die. During the forming process, the back of the titanium pipe is pulled and forced to thin, and the inner pipe wall is pressed and thickened, resulting in uneven or wrinkled wall thickness. In addition, the back of the titanium pipe is subject to erosion and corrosion during use. Due to the thin back wall, it is easy to be damaged early, The overall service life of the pipeline is greatly reduced.

4. Cast titanium pipe: although it is a seamless titanium pipe, the wall thickness (at least 5mm) can not match the pipe wall thickness (2mm- 4mm), which increases the transmission resistance and poor surface finish. More importantly, there are a large number of defects such as pores caused by manufacturing, which seriously affect the corrosion resistance and service life.

- Materiais de titânio

- Tubo e tubo de titânio

- Barra de titânio

- Forjamento de titânio

- Encaixe de tubo de titânio

- Produto Civil de Titânio